Stratiform

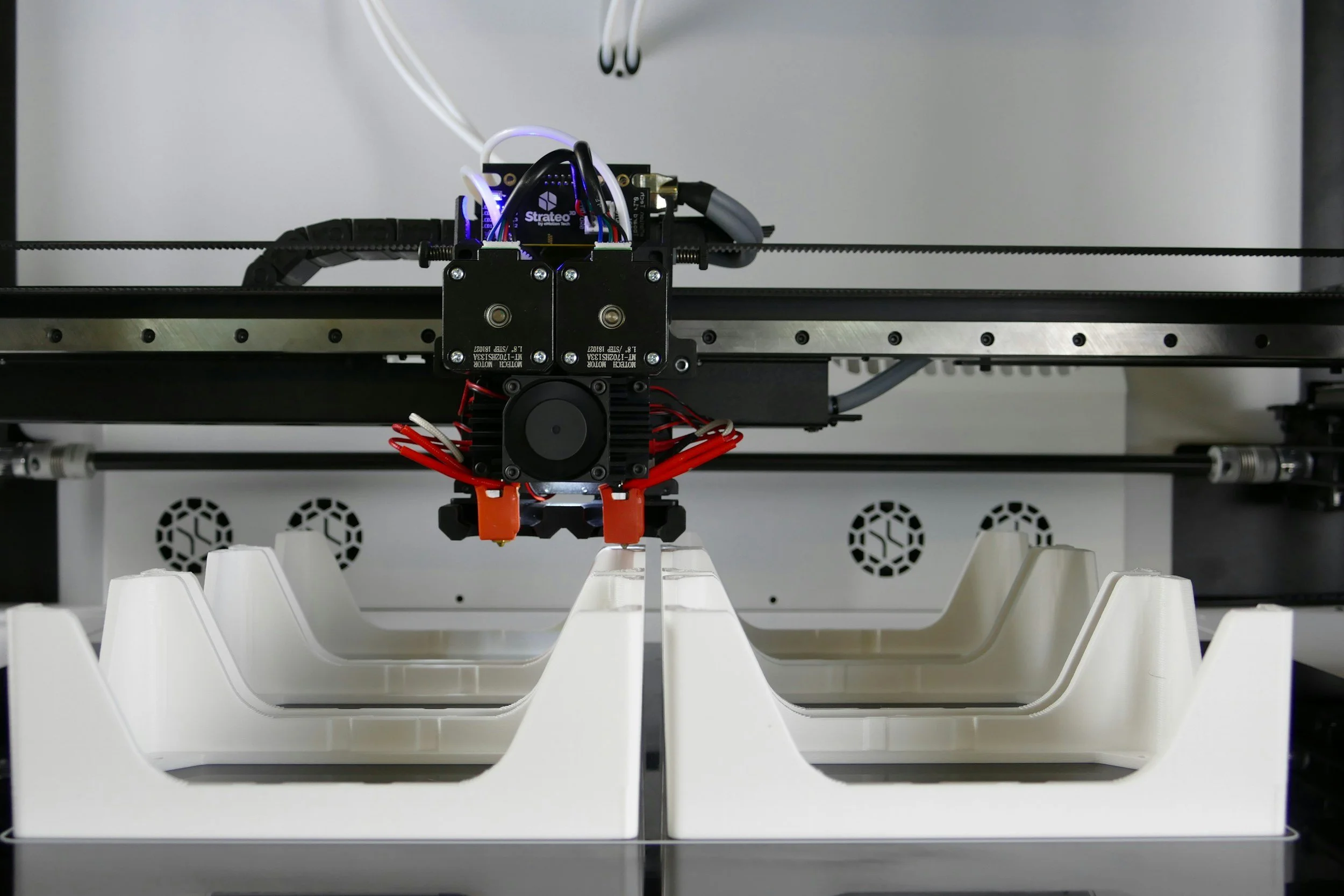

Industrial Additive Tooling for Production Environments

We engineer structural polymer tooling that reduces lead time, withstands real production loads, and keeps manufacturing moving.

Industries

Manufacturing & Production

Remove Tooling Delays from Your Production Schedule.

We manufacture validated polymer tooling that replaces slow, overbuilt solutions and supports repeatable, reliable production.

Industrial Automation & Robotics

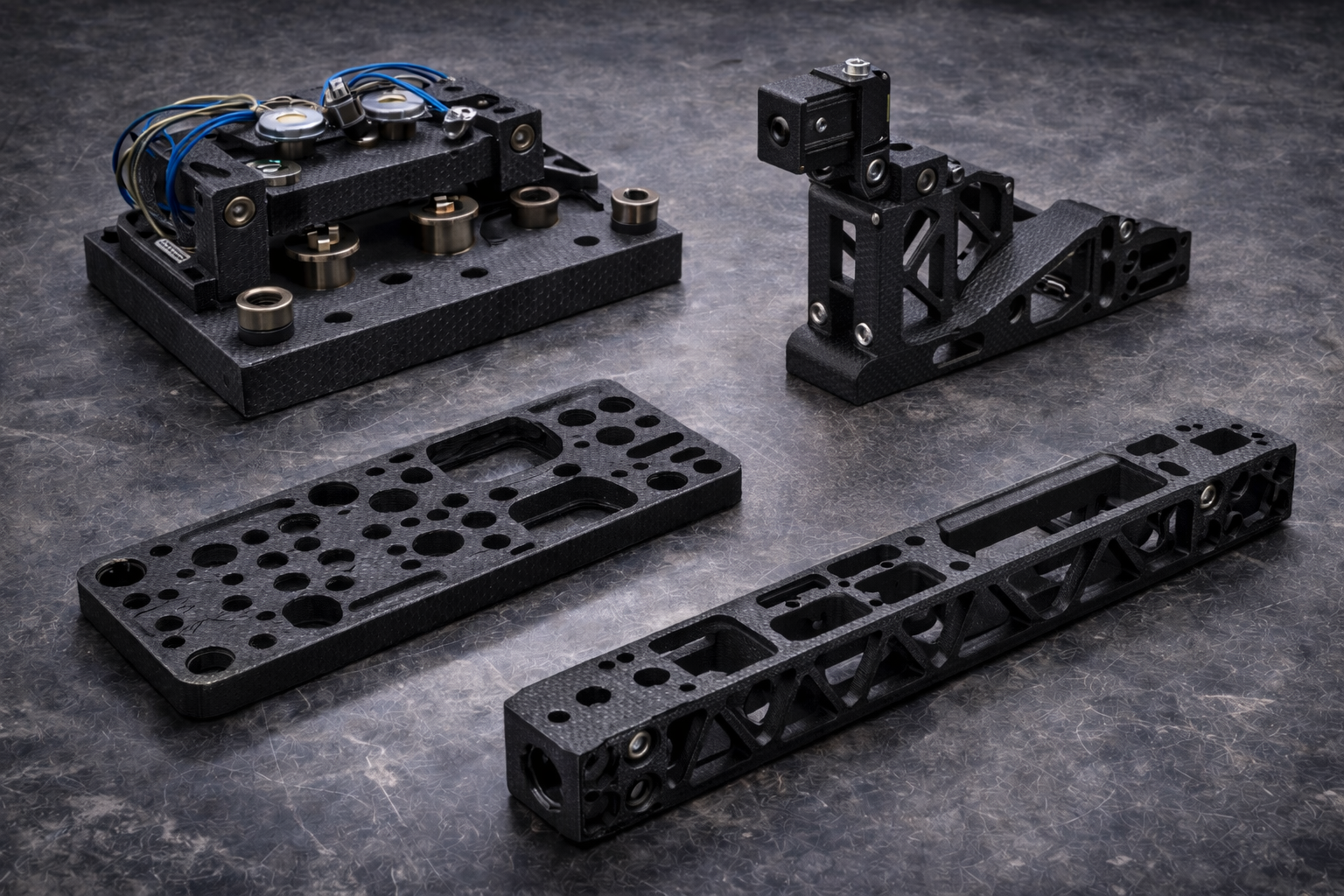

Stop Letting Tooling Limit Cycle Time.

Heavy or overbuilt end-of-arm components increase inertia and slow deployment. We produce structurally validated polymer tooling that reduces mass and supports faster commissioning.

Automotive & Performance Manufacturing

Stop Overbuilding for Automotive Environments.

Heat, vibration, and chemical exposure require intelligent material selection — not heavier parts. We deliver validated polymer components engineered for sustained stress and reliable performance.

Our Services

We design and manufacture high-performance additive tooling for production environments, including jigs, fixtures, end-of-arm tooling, and structural components. Our solutions are engineered to replace machined aluminum where appropriate, reduce lead times, and support repeatable production programs.

We engineer components specifically for additive manufacturing — optimizing for load cases, thermal exposure, wear conditions, and material performance. Rather than replicating machined parts, we redesign for strength, weight reduction, and production efficiency.

We reverse engineer existing components and tooling to restore functionality, improve durability, and reduce downtime. Whether replacing obsolete parts or improving legacy tooling, we deliver rapid, production-ready solutions built for repeat use.

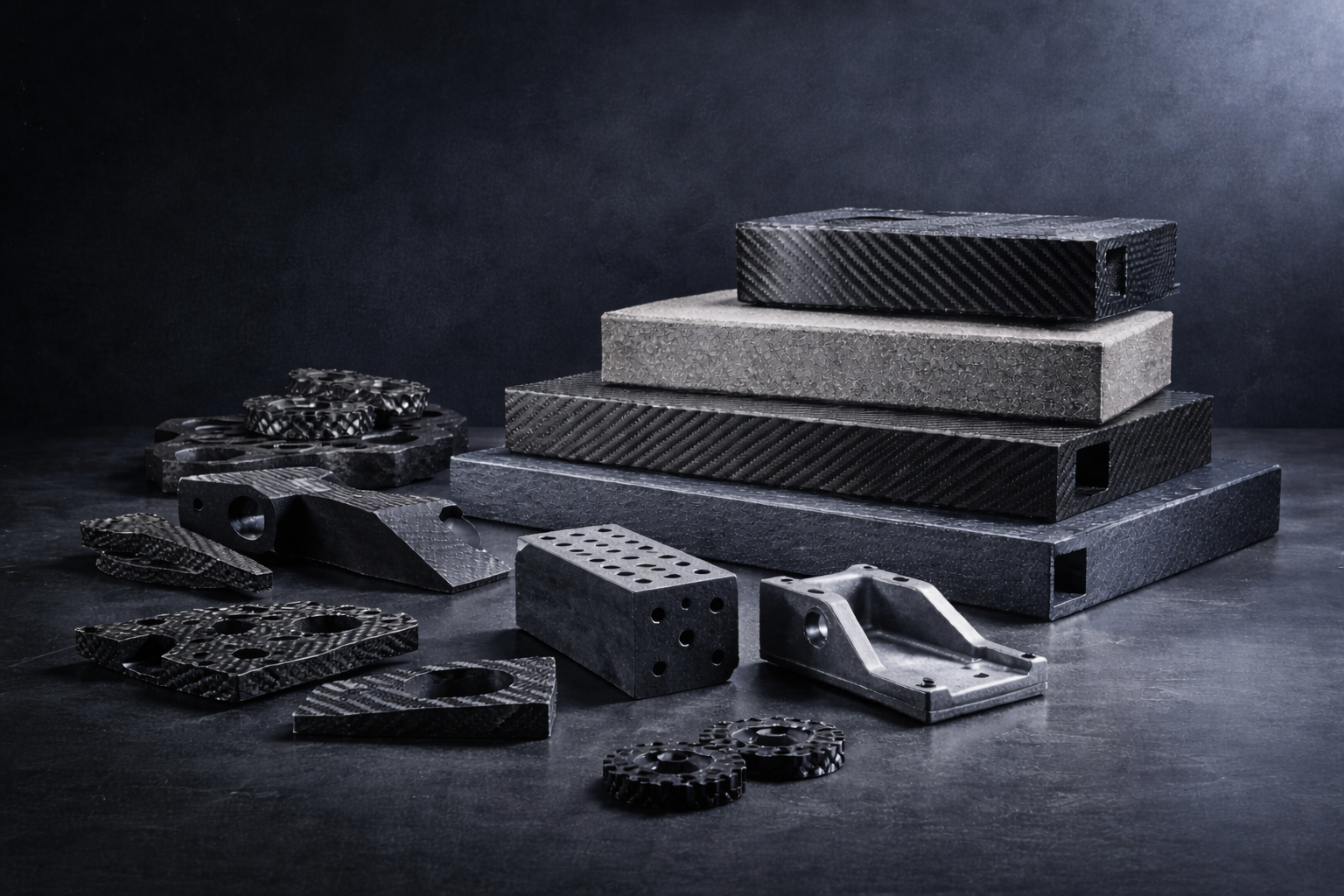

Engineering Grade Materials

-

PPS-CF is a high-temperature structural thermoplastic with excellent tensile modulus retention under thermal exposure and strong chemical resistance.

Its low creep characteristics under sustained load make it suitable for heated tooling, chemically exposed fixtures, and aluminum replacement in thermally demanding production environments.

-

PPS-GF is a dimensionally stable, high heat-deflection polymer optimized for compressive strength and rigidity.

Compared to carbon fiber variants, it offers improved impact tolerance and balanced mechanical properties, making it well suited for structural housings, mechanically fastened assemblies, and thermally exposed tooling.

-

PA6-CF is a high stiffness-to-weight structural polymer with elevated tensile modulus and strong bending resistance along fiber orientation.

It is commonly used for load-bearing jigs, fixtures, and end-of-arm tooling where rigidity and weight reduction are critical; moisture absorption must be considered in precision applications.

-

PA12-GF30 is an engineering thermoplastic with enhanced compressive strength, improved wear resistance, and lower moisture absorption compared to PA6 systems.

It is well suited for precision positioning blocks, inspection fixtures, wear guides, and structural mounting components requiring dimensional stability.

-

Polycarbonate is a high-impact engineering thermoplastic with good tensile strength and moderate heat resistance.

It provides strong toughness and energy absorption, making it suitable for structural housings, guards, and moderately loaded tooling where impact performance is prioritized over maximum stiffness.

-

PC-CF is a reinforced polycarbonate with increased tensile modulus and reduced deflection under load compared to standard PC.

It delivers improved rigidity and thermal stability for structural brackets and load-bearing components, though it sacrifices some impact resistance relative to unfilled polycarbonate.

-

ASA is a UV-stable engineering thermoplastic with moderate tensile properties and good environmental resistance.

It is commonly used for protective covers, housings, and moderate-load components exposed to outdoor or elevated temperature conditions.

-

PETG is an impact-resistant thermoplastic with good chemical tolerance and moderate mechanical strength.

It is typically used for light-duty tooling, guards, and functional components where structural loading and thermal exposure are limited.

Follow us on social

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!